Description

What Is a Vibro Hammer Sock Absorber?

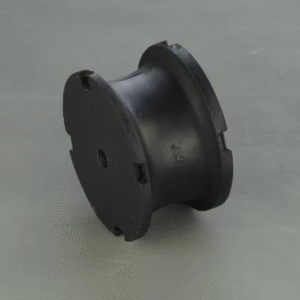

A vibro hammer sock absorber is essentially a vibration-dampening device—commonly used between a crane and a vibro hammer—to absorb and isolate vibrations during pile driving or extraction operations.

These absorbers are typically built with a durable hollow-rubber spring, sometimes integrated into an articulated metal frame. You’ll often see them described as shock absorbers, vibration dampeners, or rubber buffers for vibratory hammers.

Key Benefits

- Significant Vibration Reduction

These devices can cut down vibration transmission by up to 90–93%, greatly reducing stress on crane booms, jibs, and operator cabins. - Extended Equipment Lifespan

Since vibrations are the main cause of premature wear, these shock absorbers help preserve crane components and minimize downtime. - Enhanced Safety & Comfort

Operators benefit from reduced noise and smoother handling—especially beneficial in populated areas or when working with sensitive loads. - Lower Maintenance Costs

Less vibration means less mechanical wear, translating to fewer repairs, prolonged maintenance intervals, and improved operational efficiency. - Compliance in Noise-Sensitive Environments

Many dampeners are designed to meet noise regulations (e.g., 83 dB thresholds), allowing safer operations even in strict urban or construction zones.

Typical Design Features

- Hollow Rubber Spring: Absorbs dynamic vibration energy effectively. These are heat-resistant and designed for cyclic loading.

- Articulated Mounting: Flexible joints that align under load and accommodate stress, preventing damage even under high forces.

- Modularity & Custom Fit: Systems are often designed to fit various cranes and hammers, offering adaptability for different load capacities and configurations.

- Certifications and Build Quality: Many come ISO-certified and meet CE or Machinery Directive standards for safety and environmental compliance.

Likely Capabilities of an Al Ehtimad Model

Though Al Ehtimad’s specific technical specs weren’t available online, based on industry standards, a vibro hammer sock absorber from a reputable supplier like them would likely feature:

- Durable hollow rubber elements for high performance under vibration

- Articulated mounting plates or shackles for load alignment and stability

- Customizability to fit cranes with specified tonnage (perhaps rated for 12–120 tons, similar to other providers)

- Compliance with ISO 9001, CE, or similar certifications, ensuring build quality and safety

- A design focused on reducing vibrations by up to 90%, protecting crane structures and operator safety

Suggested Structure for a Detailed Description

Title: Al Ehtimad Vibro Hammer Sock Absorber – Comprehensive Overview

- Product Overview

A robust vibration-dampening device engineered to mount between cranes and vibro hammers, reducing structural stress and improving operational safety. - Core Components & Design

- Heat-resistant hollow-rubber spring for shock and vibration absorption

- Articulated metal joints/mounts to align load force direction

- Modular design for varied crane/h hammer compatibility

- Performance Highlights

- Up to 90–93% vibration reduction

- Applications across pile driving and extraction tasks

- Compliance with safety and noise regulations

- Operational Benefits

- Increased crane lifespans

- Smoother operator experience

- Cost savings from lowered maintenance and downtime

- Urban-friendly operation in compliance with noise standards

- Quality & Custom Options

- Likely ISO certifications and CE compliance

- OEM/ODM custom design support for specific crane or hammer models

- Use Cases & Scenarios

- Driving piles or extracting sheet piles in urban settings

- Protecting crane operators and equipment in infrastructure construction

- Handling delicate tools or sensitive payloads prone to vibration damage

Reviews

There are no reviews yet.